Polished Top Cover

SB Engineering valve Spring Compressor

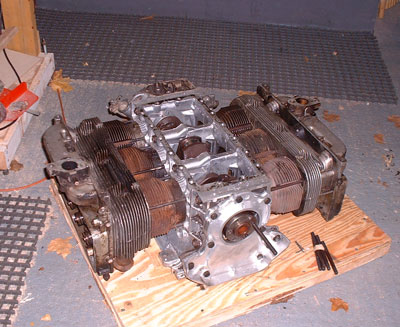

A bit of weekend 'case-cleaning'!!!

The Next steps...(all references to the William Wynne manual)

We intend to use dye pen inspection for the crankcase, using a set of aerosols (dye, cleaner and developer).

Crack check crankshafts and con-rods

Modify cranks to accept safety shaft, as WW's drawings. Page 28 of the

manual....using the drawing on page 29. We intend to omit the roll pin,

avoiding pressing the flange off the crank and use Loctitie (discussion

on page 30).

Grind cranks 0.010".

Check rods for straightness and balance them.

Fit new OT10 camshaft with new standard gear installed (from Clarkes

Corvair Parts) and new standard hydraulic lifters. Page 34

Fit new ARP con rod bolts. Page 40

New Main Bearings.

Assemble bottom end, re-using original crankcase through bolts, with new

nuts.

Fit new 0.020" oversize TRW forged pistons (with new pins and rings)

in

re-bored barrels.Page 41

Fit new oil pump.

Looks just like an aero engine!!!

Corvair engines arrive using air freight from Florida to BHX....William Wynne has already done a bit of work on reducing the parts to those needed. Next back to the PFA to discuss our next moves!

Here are pictures of the cores ready to ship

The two engine crates weigh 195 pounds each, and the parts box is 75 pounds. . They are each in a wooden crate, with another crate for additional internal components. While the engine parts are still dirty, William has put a lot of effort into getting the best cores possible. The primary difficulties people have with core engines are damaged head studs and helicoiled spark plug holes. While neither is really a big deal to fix in the States, he wanted to find us a pair of cases with perfect studs and heads without helicoils with threads in good condition. All of the other components of the motor can be rebuilt to aircraft specs. The cylinders will all clean up with a 20/1,000" overbore, and the cranks could be run as they are but should be ground 10/10. To save shipping weight, they've thrown away components like lifters, which are always replaced. The price of each motor is $299. The cost of crating is $100 per motor. The dimensions of each crate are 24"x14"x30". The box of components is slightly smaller.

Quotes for shipping are about $380 at the moment.....

The Engine of choice for G-BYLD and G-OPJS ???

Dear Experimental Aircraft Builder, Thank you for the interest in my Corvair engine conversion plans and components. I feel that the direct drive Corvair engine is an excellent choice for VFR sport aviation aircraft requiring a 100hp to 125hp engine. The Corvair engine is a 164 cubic inch (2,700cc), horizontally-opposed, six-cylinder, air-cooled power plant. General Motors produced 1.7 million Corvairs between 1960 and 1969. All of these high quality engines have hydraulic lifters, torsional vibration dampeners, full flow oil systems, spin on oil filters, and aluminum cases and cylinder heads. Corvair engines have been powering Experimental Aircraft since 1960. Flying hundreds of hours, EAA members Bernie Pietenpol and Waldo Waterman demonstrated that the Corvair engine made an excellent aircraft power plant. Today, the Corvair engine still represents an excellent choice for home builders. With my up-to-date research and current Conversion Manual (written in 1996 and updated in 1999), the Corvair is an easy engine to adapt to aircraft use. I provide information, drawings and components for converting Corvair engines for aircraft use. Complete engines are available on a special order basis. Please feel free to call with any further questions you may have. Thank you for your interest concerning my products. For more information on the development of my manual, please see my Technical Support Page. Please see my Online Catalog for more information on my products. Sincerely, William Wynne EAA #331351